MBS resin: The invisible armor that gives new life to PVC

PVC (polyvinyl chloride), as a widely used general-purpose plastic, meets numerous demands in modern industry and daily life. However, its inherent brittleness and insufficient weather resistance and other defects have always restricted its application in high value-added fields. The emergence of MBS resin is like an invisible armor tailor-made for PVC. Through ingenious modifications at the molecular level, it has brought new vitality to traditional materials.

Rebirth of Resilience: The Transformation from Fragile to impact-resistant . The brittleness of PVC has once been a headache for countless engineers. A common PVC sheet may shatter into pieces with a light drop at low temperatures.The core-shell structure of MBS resin is like countless miniature "energy buffers". The inner styrene-butadiene rubber core layer can absorb impact stress, while the outer hard shell layer acts as a protective net, firmly locking the path of crack propagation. This dual protection mechanism enables PVC products to remain flexible even in extremely cold environments, completely escaping the fate of brittleness and cracking.

The Art of Transparency: Break the contradiction between toughening and light transmission. In the field of plastic modification, toughening and transparency are often a pair of irreconcilable contradictions. Traditional toughening agents often come at the expense of transparency, while MBS resin achieves "invisible toughening" by precisely regulating the refractive index of methyl methacrylate (MMA) in the shell layer to match that of PVC. Whether it is the clarity of medical infusion bags or the crystal clarity of food packaging films, MBS resin enables PVC to maintain its functionality while still conveying the beauty of the material.

Flowing Wisdom: The Invisible Driver of processing efficiency. In industrial production, the fluidity of PVC melt directly determines the efficiency and accuracy of injection molding. The hard shell layer of MBS resin acts like countless micro-lubricants at processing temperatures, which not only reduces the melt viscosity but also avoids energy waste caused by excessive plasticization. This kind of "subtle and imperceptible" improvement has significantly shortened the production cycle of complex and precise components, providing more possibilities for the lightweight design of automotive parts and electronic enclosures.

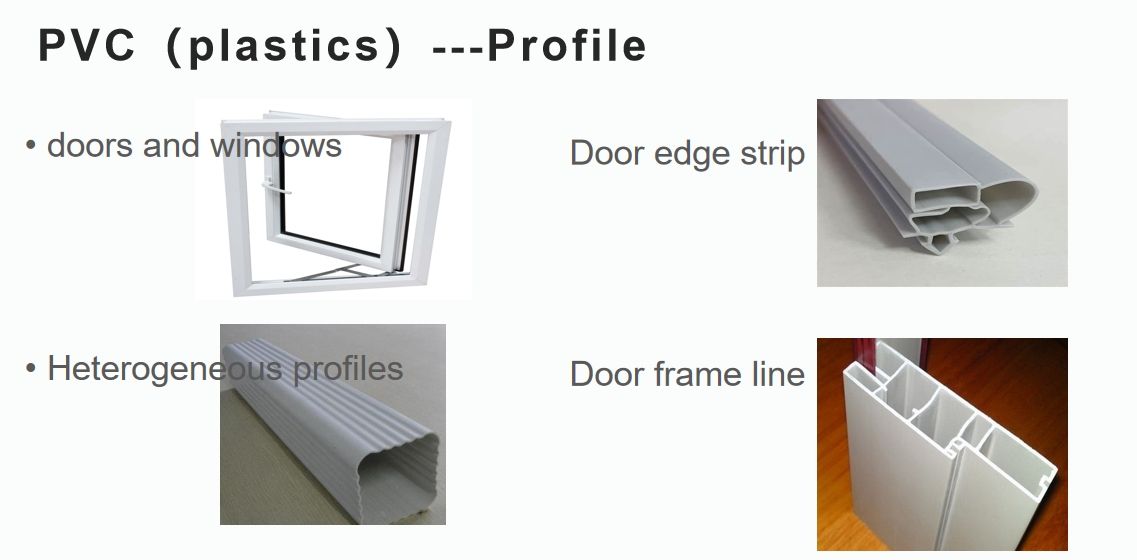

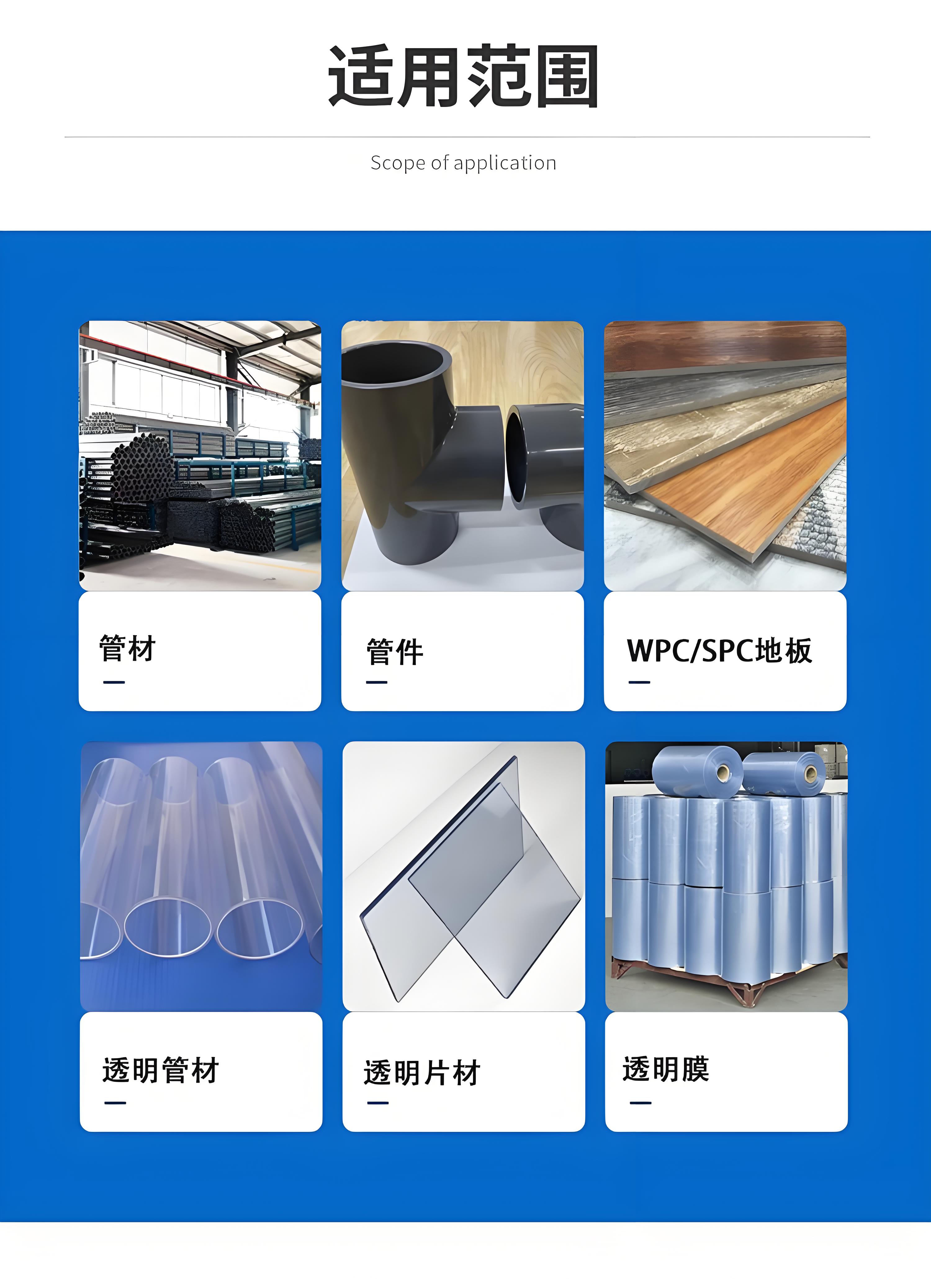

Evolution of weather resistance: Stability in race against time. PVC products used outdoors often turn yellow and powderize due to ultraviolet erosion. The double bond structure in MBS resin was once the root cause of this defect. Nowadays, by hydrogenation technology to "reinforce" molecular chains or by introducing UV-absorbing groups, the new generation of MBS resins is breaking through the bottleneck of weather resistance. From architectural window frames to outdoor pipes, the modified PVC is no longer afraid of the tests of sunlight and wind and rain, demonstrating a longer life cycle.

Green Future: Role Reconfiguration in sustainable transition . Under the wave of environmental protection, the innovation of MBS resin is not limited to performance improvement. The introduction of bio-based monomers and the exploration of recyclable designs have quietly integrated this traditional modifier into the circular economy system. When discarded PVC packaging is efficiently recycled through modification technology and medical products are free from the shadow of plasticizer migration, MBS resin is leading the PVC industry towards a cleaner and safer future.

Shandong AXA Chem Co.,Ltd

May 8, 2025

Leave a Reply

Your email address will not be published. Required fields are marked *