The types and applications of HCPE

High chlorinated polyethylene (HCPE) is mainly classified into three types based on viscosity and application. Their characteristics and application fields are as follows:

1、HCPE-H (high viscosity type)

Characteristics : molecular weight 200,000-250,000, chlorine content 65±2%, viscosity ≥35 seconds (apply -4 cups at 25℃)

Application:

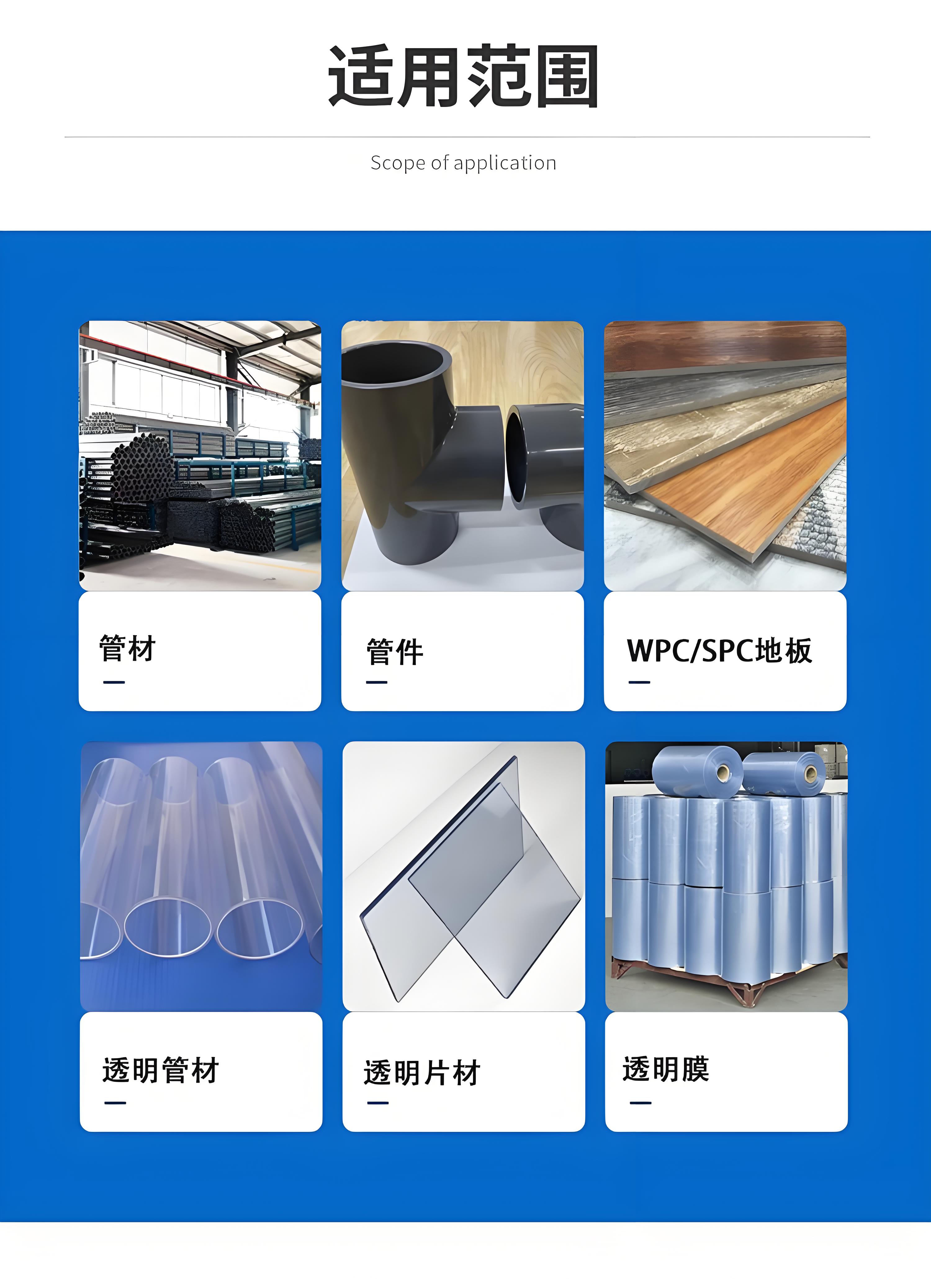

It is specially designed for high-strength bonding of PVC pipes, pipe fittings and plates, with fast curing speed and no freezing at low temperatures

Metal material adhesives, such as steel structure joint sealing

2. HCPE-M (medium viscosity type)

Characteristics: molecular weight 150,000-200,000, viscosity 20-35 seconds,

chlorine content 65%

Application:

Anti-corrosion field: It can replace chlorosulfonated polyethylene and is used asa heavy-duty anti-corrosion coating for chemical equipment, ships and offshore platforms.

Fire protection field: Fireproof coatings for steel structures, fireproof layers for concrete buildings;

Underground engineering: Outer protective coating for buried pipelines;

3. HCPE-L (low viscosity type)

Characteristics: Molecular weight 80,000-120,000, viscosity 15-20 seconds,

surface drying time ≤30 minutes.

Application:

Quick-drying scenarios: container coatings, road marking paints;

Composite coating: Blended with acrylic/alkyd resin to enhance toughness;

Special protection: Firework bright bead moisture-proof layer, flame-retardant

coating for lithium battery casing.

Shandong AXA Chem Co.,Ltd

July 1st, 2025

Leave a Reply

Your email address will not be published. Required fields are marked *