Chlorinated polyvinyl chloride (CPVC): The innovative power of modern industrial materials

Chlorinated polyvinyl chloride (CPVC): The innovative power of modern industrial materials

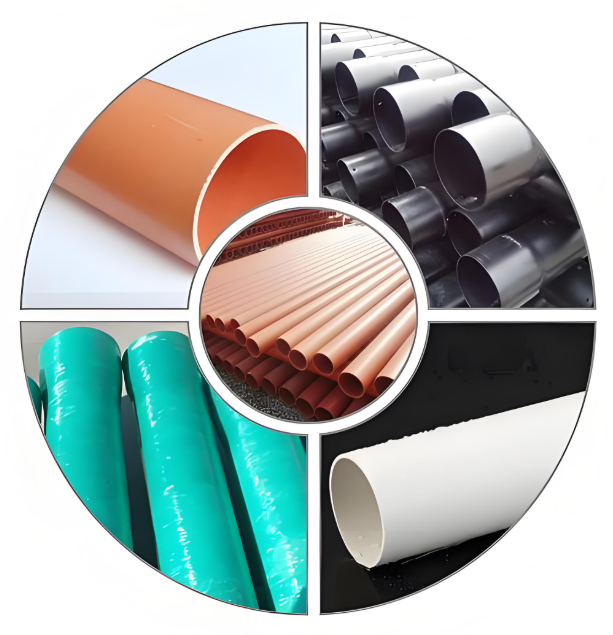

Chlorinated polyvinyl chloride (CPVC) is a high-performance material made by deep chlorination modification of common polyvinyl chloride (PVC). Compared with PVC, its chlorine content has increased from 57% to 63%-74%. This change in chemical structure has endowed CPVC with breakthrough performance and made it a model for the upgrading of modern industrial materials.

Performance Breakthrough: From temperature limits to chemical tolerance

The most significant improvement of CPVC lies in its heat resistance. Ordinary PVC is prone to softening and deformation above 60℃, while the glass transition temperature (Tg) of CPVC can reach 110-130℃, enabling it to withstand 93℃ hot water for a long time and 110℃ hot medium for a short period. This characteristic enables it to replace metals in the field of high-temperature pipes. For instance, 70% of hotel hot water systems in North America use CPVC pipes. Meanwhile, chlorination treatment enhances chemical stability and can withstand corrosive media such as 40% sulfuric acid and 20% sodium hydroxide, making it the preferred material for the inner lining of chemical storage tanks.

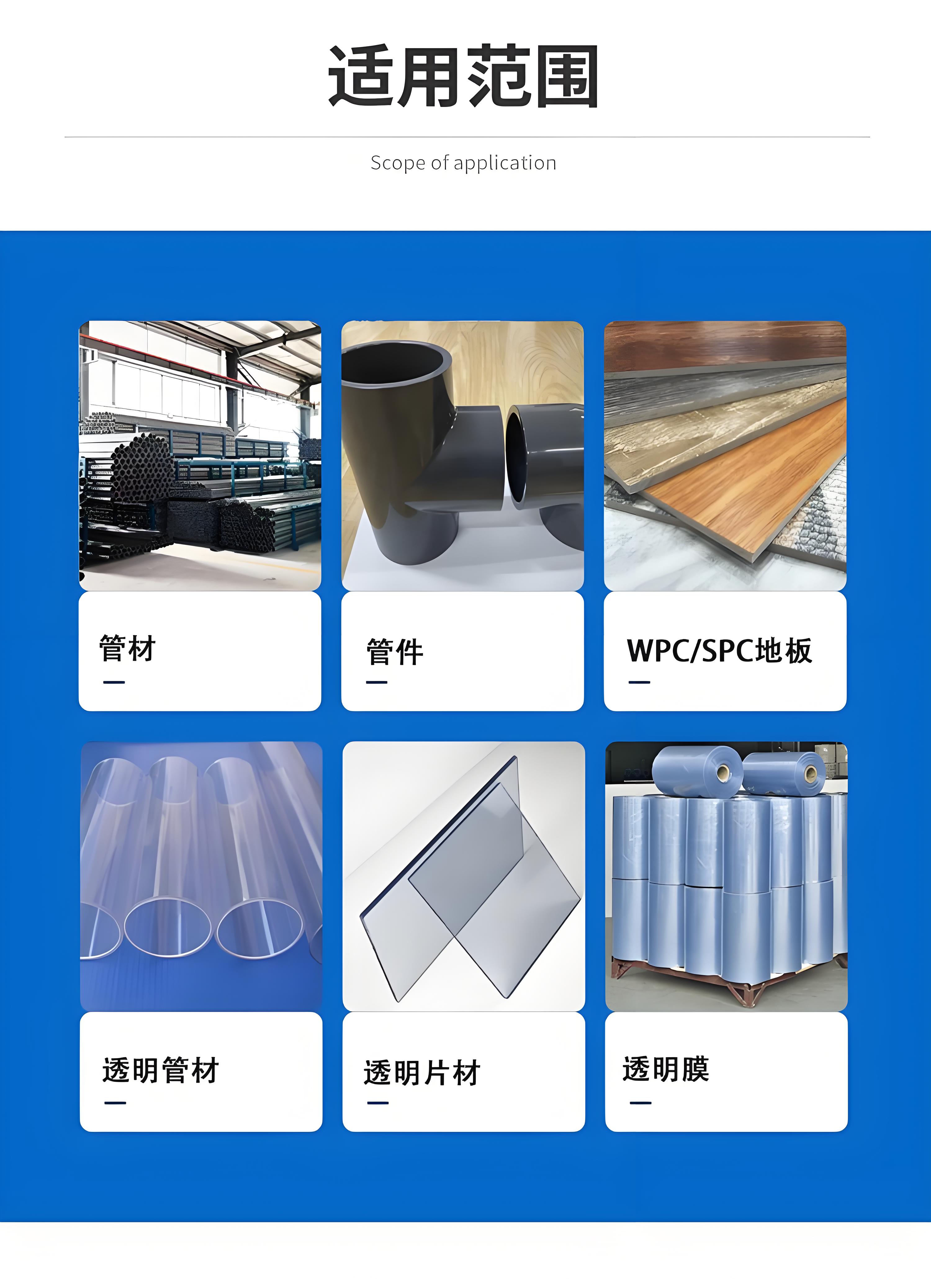

Applied Innovation: From building Plumbing to New Energy

In the field of construction, the CPVC fire sprinkler system, with its flame retardancy (oxygen index ≥60) and low smoke characteristics, can maintain structural integrity for more than two hours during a fire. In recent years, CPVC has further ventured into the new energy industry: the electrolytic cell frames it prepares can withstand the strong acid environment of hydrogen fuel cells, and their service life is three times longer than that of stainless steel. In photovoltaic power stations, the UV aging resistance of CPVC cable protection pipes is 50% higher than that of ordinary PVC.

Environmental value: Green choice throughout life cycle

The carbon emission intensity of CPVC is only 1/8 that of galvanized steel pipes, and its production energy consumption is 75% lower than that of copper pipes. In the LEED green building certification of the United States, the use of CPVC pipes can achieve a score weight of 10%. Its service life of over 50 years and 100% recyclability perfectly meet the demands of the circular economy.

This material, which achieves a performance leap through molecular design, is reshaping industrial standards with the power of technology and demonstrating the breakthrough of human wisdom over the limits of materials. In the future, with the advancement of modification technology, CPVC may open up broader application blueprints in fields such as aerospace and deep-sea engineering.

Shandong AXA Chem Co.,Ltd

May 12, 2025

Leave a Reply

Your email address will not be published. Required fields are marked *